Walton compressor factory starts with export orders from Germany

2 || risingbd.com

Staff Correspondent: The newly built Walton Compressor factory has received an export order from German based world’s leading compressor manufacturer ‘Secop Gmbh’ just after the inception of production process.

The Walton authorities said, documents of the export orders were presented to Finance Minister Abul Maal Abdul Muhith while he was inaugurating the country’s first ‘Walton Compressor Unit’ at Chandra in Gazipur on April 06, 2017.

Initially, the German based company placed an order to Walton Compressor unit for supplying 4 lakh casting parts to them, the Walton officials said adding, the shipment procedures of the export orders will be completed within this month.

They also informed that Walton already inked an agreement for exporting about one million pieces of casting parts annually to Secop Gmbh.

It was learnt that Secop has a demand for about 7 million casting parts annually to make various sorts of compressors. Walton officials think that they have a chance to meet the entire demands of the Germen based company with the Bangladesh’s made casting parts.

Apart from Secop, Walton is also going to receive more orders from some Japan and South Korea based companies for supplying about 2 million compressor’s parts, the local company’s officials said.

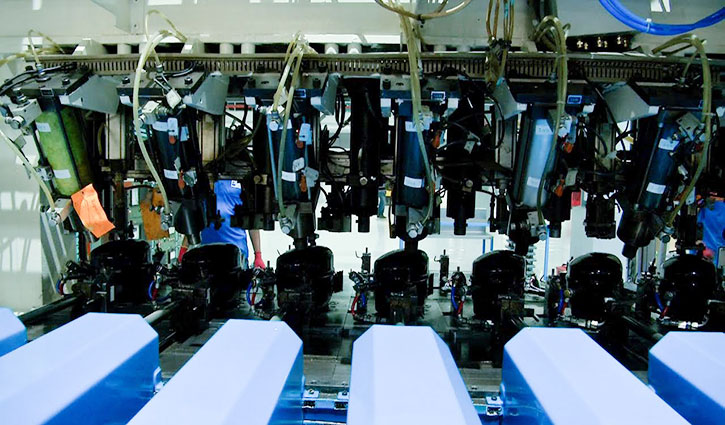

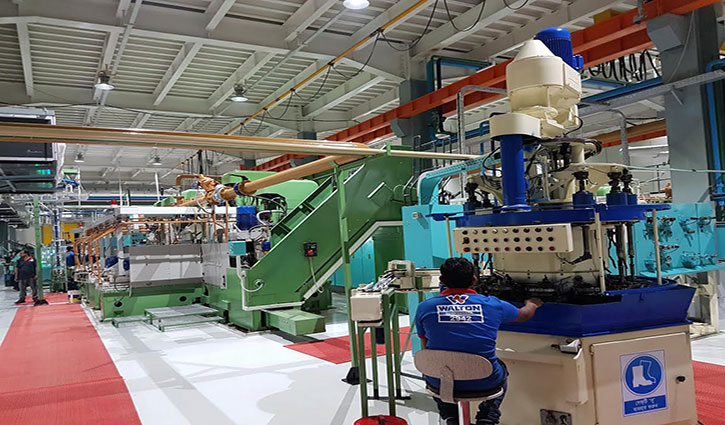

After the inauguration, representatives from different compressors manufacturers and importers of various countries are visiting Walton Compressor unit. Witnessing the world’s state-of-the art compressors’ production process at Walton factory, most of the representatives are showing keen interest to import Walton compressors and parts.

Walton set up the country’s first composite factory for manufacturing compressor on about 16 lakh square feet of land through establishing steel, zinc, aluminum, copper casting, foundry, testing and metal processing units. To ensure international standard of the produced compressors and its necessary parts, Walton has build ‘Quality Control’ and ‘Research and Development’ departments.

Ashraful Ambia, executive director of sourcing engineering of Walton Group and in-charge of compressor project, said, “Just after the inauguration, the production of compressors and necessary raw materials like casting parts, plastic parts, insulating copper wares, screws, tubes and pipes, sheet metals and so on are going on in full swing.”

Initially, Walton compressor unit has a capacity of producing 4 million ultra-hybrid quality’s compressors annually, he said adding, they set a target of raising the annual production capacity to 1.2 crore. Of which, a lion portion would be exported after meeting the local demands.

In addition, the newly built compressor unit has a capacity of producing 4.5 million casting parts annually, he informed. Now, Walton is producing the compressors’ parts with the world’s advanced Danish technology based automatic metal casting plant.

Uday Hakim, senior operative director of Walton Group, said, Producing compressors is a great milestone for Walton as well as Bangladesh’s high-tech industry.

Bangladesh is now footing its steps with a new appearance in the global market, he added.

risingbd/Dhaka/April 15, 2017/A K Azad

risingbd.com